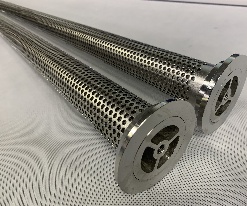

Slotted pipes

Product Description:

Slotted pipes are manufactured by laser cutting process without contact operation. This process can effectively avoid undesirable factors which will cause the deformation of the base pipe.

Laser cutting process uses windows interface for easy operation and accurate calculation.

All slots are de-burred, cleaned and drift tested according to API standards. Base pipe are per API casing or tubing specification with diameters from 1.5 inch to 18 inch. Pipe lengths of any diameter are available.

Slotted casing pipes Patterns: line pattern, staggered pattern,multiple staggered gang pattern and multiple line pattern are applied. Each has its own characteristics.

Slotted Geometry: Slotted shapes are classified into two types: straight cut slot and keystone cut slot. Compared with straight slot, keystone slot has higher resistance against plugging for its inter size is larger than the surface size. Once the sand entering the keystone slot, the possibility of clogging will drop sharply.

Slotted size: Slotted pipes slots consists of slot length, slot width, slot density and slot distribution. All these parameters can be be spoken to achieve the required open area. Fox example, multiple staggered pattern or gang pattern significantly increase the open area compared with single cut pattern.

-

Features:

1. Diameter: determined by the borehole diameter and pump size.

2. Material: stainless steel, carbon steel, galvanized carbon steel according to the PH value of water.

3. Slot size: as per the size of filter medium and gravels.

4. Collapse strength and tensile strength: decided by the depth of screen installed.

5. Unit length: 2.9 and 5.8m fit for the container.

6. Connection ways: Welding, API Thread(Pin and Box), or Flange.

7. CO,FORM A, FORM E, CIQ,COC,SASO and other required certificate can be provided.

-

Application:

Slotted pipe is a robust and effective device for sand control in the horizontal completion wells and other thermal heavy oil recovery. Its excellent properties in withstanding installation loads and operation loads make it premier choice.

How Many Holes Needed To Achieve a Certain Open Area?

N = 12*3.14*D*C/100*W*L

N = the number of slots per foot.

D = Outside diameter of the liner (in inches).

C = Open area percentage.

W = selected slot width (in inches).

L = Length of slot (inches).

Specification

| Outside Diameter: | 2 3/8”-20” |

| Thickness: | max 16mm |

| Slot width: | 0.1-6mm |

| Slot length: | 30-500mm |

| Slotted patterns: | straight or keystone slots |

| The open area: | according to cusomer’s requirements |

| Pipe length: | 0-12m |

| End connection type: | plain ends, flange or threads |