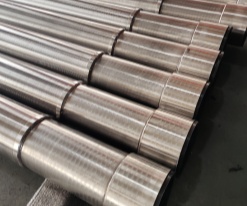

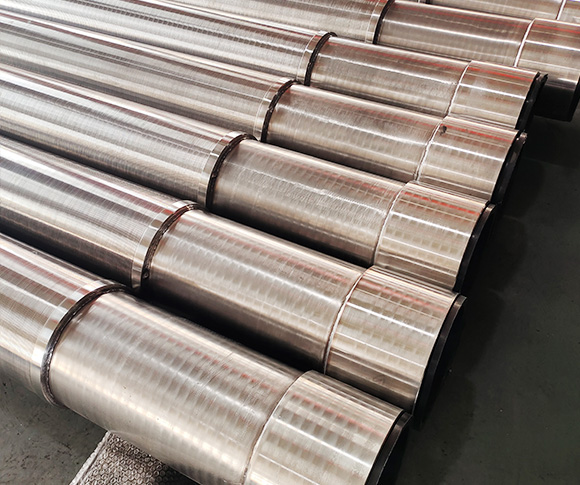

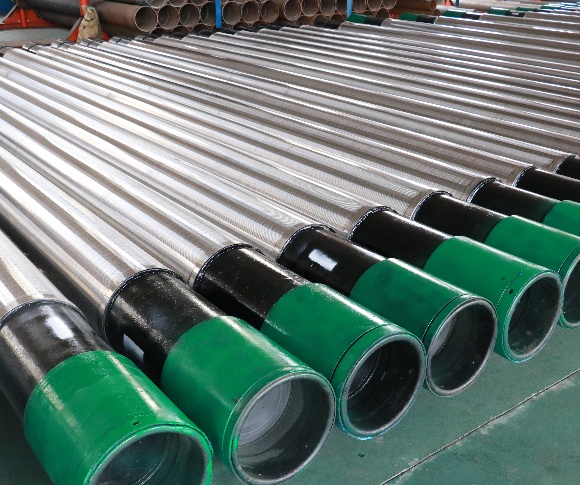

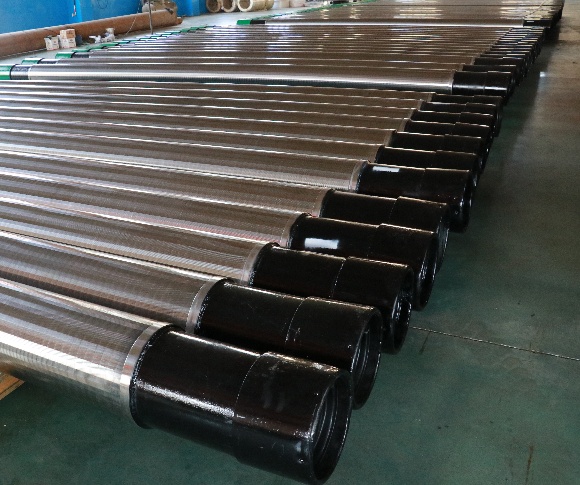

Pipe Base Screen

- Product Description:

- Pipe Base Screen consists of a wire-wrapped screenjacket and a base pipe.Screen and pipe are welded together to make a rugged, reliable unit for deep vertical wells and long, horizontal remediation of supply wells. The pipe-based screen is recommended when high collapse resistance is required and when the screens’ length generates a high longitudinal constraint.

Features & Benefits

1. High flow capacity. The jacket is made of vee wire well screen this allow more water or oil to enter at much lesser frictional head loss and the efficiency of well is improved appreciably.

2. Perfect integral strength and strong anti-deformation ability The internal part of filtration jacket is supported by base pipe and the outer protective shroud can be fixed outside the filtration jacket if necessary.

3. More choice: The screen jacket material can be stainless steel or low carbon steel,it is can as per your requirement.

4. Slot with high density, low flow resistance .Slot density are 3~5 times as traditional slotted screen, with low flow resistance. It is conducive to increase production of oil or gas.

5. Good manufacturability makes high efficiency, low cost, and large-scale production achievable.

Specification

| BASE PIPE | SLIP ON SCREEN JACKET | |||||||||

| Nominal Diameter | Pipe OD (mm ) | Weight Ib/ft W. 1 [mm ] | Hole size in | Holes per foot | Total Area of holes in2/ft | Screen OD (in) | Open area of screen in2/ft SLUI | |||

| 0.008" | 0.012" | 0.015" | 0.020" | |||||||

| 2-3/8 | 50 | 4.6 [4.83] | 3/8 | 96 | 10.60 | 2.86 | 12.68 | 17.96 | 21.56 | 26.95 |

| 2-7/8 | 73 | 6.4 [5.51 ] | 3/8 | 108 | 11.93 | 3.38 | 14.99 | 21.23 | 25.48 | 31.85 |

| 3-1/2 | 88.9 | 9.2 1 &45 ] | 1/2 | 108 | 21.21 | 4.06 | 18.00 | 25.50 | 30.61 | 38.26 |

| 4 | 101.6 | 9.5 [5.74] | 1/2 | 120 | 23.56 | 4.55 | 20.18 | 2&58 | 34.30 | 42.88 |

| 4-1/2 | 114.3 | 11.6 [6.35] | 1/2 | 144 | 28.27 | 5.08 | 15.63 | 22.53 | 27.35 | 34.82 |

| 5 | 127 | 13 [& 43 ] | 1/2 | 156 | 30.63 | 5.62 | 17.29 | 24.92 | 30.26 | 38.52 |

| 5-1/2 | 139.7 | 15.5 [6.99] | 1/2 | 168 | 32.99 | 6.08 | 18.71 | 26.96 | 32.74 | 41.67 |

| 6-5/8 | 168.3 | 24 [8.94] | 1/2 | 180 | 35.34 | 7.12 | 21.91 | 31.57 | 38.34 | 48.80 |

| 7 | 177.8 | 23 [8.05] | 5/8 | 136 | 42.16 | 7.58 | 23.32 | 33.61 | 40.82 | 51.95 |

| 7-5/8 | 194 | 26.4 [8.33] | 5/8 | 148 | 45.88 | 8.20 | 25.23 | 36.36 | 44.16 | 56.20 |

| 8-5/8 | 219 | 32 I 8.94 ] | 5/8 | 168 | 51.08 | 9.24 | 28.43 | 40.98 | 49.76 | 63.33 |

| 9-5/8 | 244.5 | 36 [8.94 ] | 5/8 | 188 | 58.28 | 10.18 | 31.32 | 45.15 | 54.82 | 69-77 |

| 10-3/4 | 273 | 45.5 [10.16] | 5/8 | 209 | 64.79 | 11.36 | 34.95 | 50.38 | 61.18 | 77.86 |

| 13-3/8 | 339.7 | 54.5 (9.65] | 5/8 | 260 | 80.60 | 14.04 | 37.80 | 54.93 | 66.87 | 85.17 |

Applications

Casing pipe and open hole environments.

Suitable for gravel-pack and standalone operations.

Sand free production in vertical or horizontal wells.